Watch Essentials: How to turn an ordinary timepiece into a luxury watch

They say that the eye wants its share too – and watches are certainly no exception. So much that the most precious timepieces not only offer a micromechanical and technical perfection that makes them unique: they are often decorated and embellished with the most prized and refined artistic techniques, turning them into a real artwork.

And this is precisely the topic we will focus on: how the great watchmaking Maisons manage to transform an object with technical content into something much more upscale.

Through the ages, the watch was primarly a sign of style

Those who approach watchmaking often believe that spending a lot of money on a watch doesn’t make sense since a watch is born to be an instrument that marks time. And this is a big mistake. Before their technical function – which is extremely important and no one can deny – watches have always been a way to garner social recognition.

Watchmaking history teaches us that the talent of the first watchmakers were considered just like the painters’ and artists’ – and they were fought over by the various courts to have a watch built that was more beautiful and sumptuous than that of their adversaries. And we can also see from the iconography of the official portraits of nobles and landed gentry that the first clocks were made not only to be worn but exhibited.

There was a practical reason for this. The inner mechanism had to be protected somehow – and the best metals to do so were precious metals, mainly silver and gold. They were easy to work with, relatively soft, and long used for jewelry, with techniques back then commonplace. And because of this, watches became, from early on, authentic jewelry pieces that were worn hanging from a chain around the neck or from an elaborate gold holder attached to the waist.

Skeletonization and engravings

Over the years, watch cases were embellished with decorations and ornaments. Some cases were cut and shaped with artistic engravings and often, as fashion dictated, decorated with carved and painted miniatures.

Over the years, this trend spread to internal movements: bridges and plates were also “skeletonized,” making holes that visually lightened the movement and made it more interesting to see. These engravings were made by hand for a long time, creating “scenes”: figures, landscapes, animals. Real miniature masterpieces of watchmaking art that mixed technique and artistic inspiration.

This tradition is still repeated today. As a result, it is pretty common to see watches that follow this fashion, which often involves the absence of the dial and the creation of a transparent backcase, through which you can see the movement ticking.

Decorations and finishes of movements

Like any artistic object, watches are often subject to embellishments such as the setting of precious stones in the cases and sometimes in the movements and the engraving of various designs on the cases and backs.

A small note: if you check a watch movement, you will probably find small red stones placed in the caliber. These are synthetic rubies that have a technical function: making the pivots of the wheels of the movement rotate better and with less friction. In this case, although they are beautiful to look at, they are there for a technical reason.

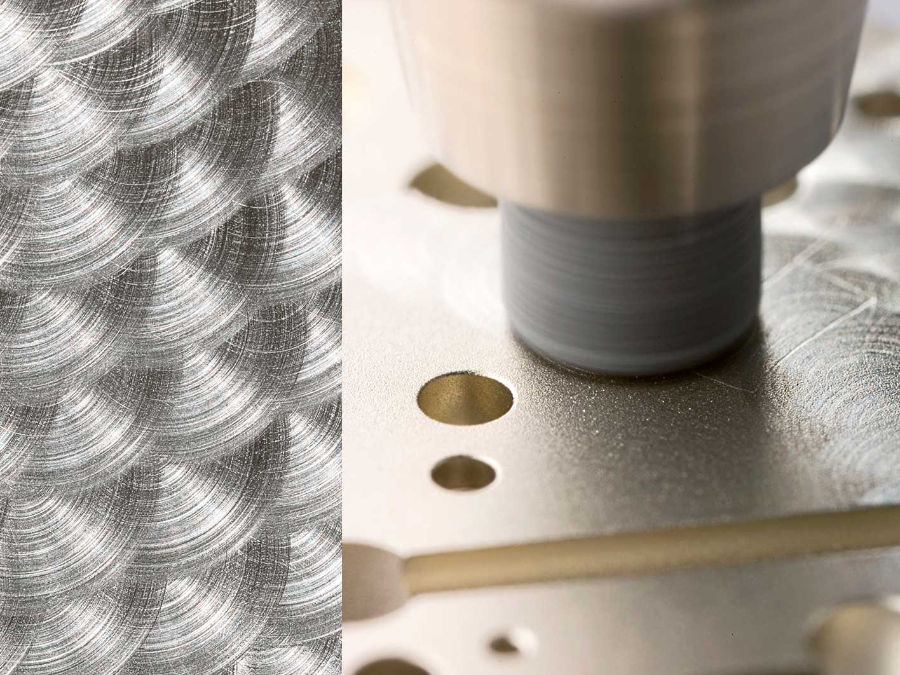

When we examine the surfaces of a quality movement, we can see that they often bear some peculiar characteristics. For example, horizontal surfaces are finished with a variety of patterns, the most common of which are two: a series of small circles close together that make up a regular pattern – the so-called “perlage” – and horizontal bands at regular intervals with a shaded effect – the so-called “Cotes de Geneve.” Once, they had a technical function: attracting dust and removing it from other parts of the movement; today, their role is primarily aesthetic.

Another typical finishing is that of anglage. If you look carefully, you will see that the horizontal and vertical surfaces of the caliber elements do not meet at right angles, but there is a 45-degree surface joining them, usually polished to a mirror finish. Also, in this case, the original reason was initially technical: all surfaces needed to be well-polished to avoid small scraps that could end up in the movement and ruin its delicate mechanisms.

The black mirror polish is instead a finishing through which the pieces are sanded with finer and finer abrasive papers until the element takes its typical shiny black color. It is a very time-consuming process. It can only be done manually – and there are very few artisans who can do it.

Finally, there is the blue coloring of the screws. Again, the original reason was technical. Steel elements, hardened at different temperatures, take on different colors according to the flame’s heat. So a hardness scale originated, in which bright blue is one of the hardest gradations. In the past, the heat had to be perfectly regulated always to obtain the same color, while today, companies use chemical treatments and the screws produced are less artistic but more uniform in color.

Case and bracelet finishes

The cases are often subject to similar finishes, especially using different types of polishing, both glossy and satin, which give the watch a slightly different and intriguing design effect, enhancing certain lines and softening others – an actual work of design architecture.

This effect is often enhanced by using different materials, such as different metals combined in the same watch, to expand the designers’ intervention. And let’s not forget the crown, which is often a tiny work of art that features different finishes for a harmonious and distinctive final effect.

Dial materials and techniques

The dial is possibly the most distinctive element of the watch, and over the years, dials have been made from the most diverse materials. Once again, it is a surface on which artists have indulged, creating striking artistic effects that know how to catch the eye of the beholder with their beauty.

It’s impossible to detail all the types of dials available, as the watch industry has used everything from metals to precious stones, glass to plastic, ceramics to mosaic, to specific processes that combine different materials into beautiful effects. We will focus on the most common ones.

Guilloche workmanship is a particular effect that was often used, especially on dials. Through a specific machine known as a rose engine, a pattern – there are many traditional ones – is applied to the entire dial or part of it. Then the dial is often enameled, leaving the three-dimensional effect of guilloche visible. Guilloche-making is a very ancient craft, as it was also found on watches dating back to 1624.

A typical material used on dials is glass, applied in the form of enamel. Typically, a metal dial is prepared and covered with this glass paste, which is then fired in a high-temperature oven. Different additives in the paste make it possible to vary the color and final result. In some particular cases, more coats can be applied to obtain a three-dimensional effect.

Porcelain is a ceramic material widely used in dials: delicate and with an opaline effect. It is applied in paste form and then fired at high temperature, obtaining delicate dials with a characteristic slightly iridescent aspect.

There are dials made from stones, both precious and not, such as dials made of meteorite. Usually, these dials are made of metal to which is stacked a very thin slice of the material. They can have other subdials, which can be made of different materials.

Marquetry dials, on the other hand, are like small mosaics of pieces of materials juxtaposed to provide geometric effects. Usually, these are small stone tiles, but in some cases, wood is used.

Finally, some dials combine the use of metals with enamels. Basically, a design is created with metal, which is then filled with enamels of various colors and then fixed through multiple firing cycles. The processes are diverse and have poetic names such as cloisonné, champlevé, and flinqué.

Indexes and hands

There are several ways to apply indexes and numerals to dials. In the most precious cases, the hour-markers are applied – in ancient times employing elements with tiny feet that were set into micro-holes in the dial – or in modern instances, printed by a pad printing process.

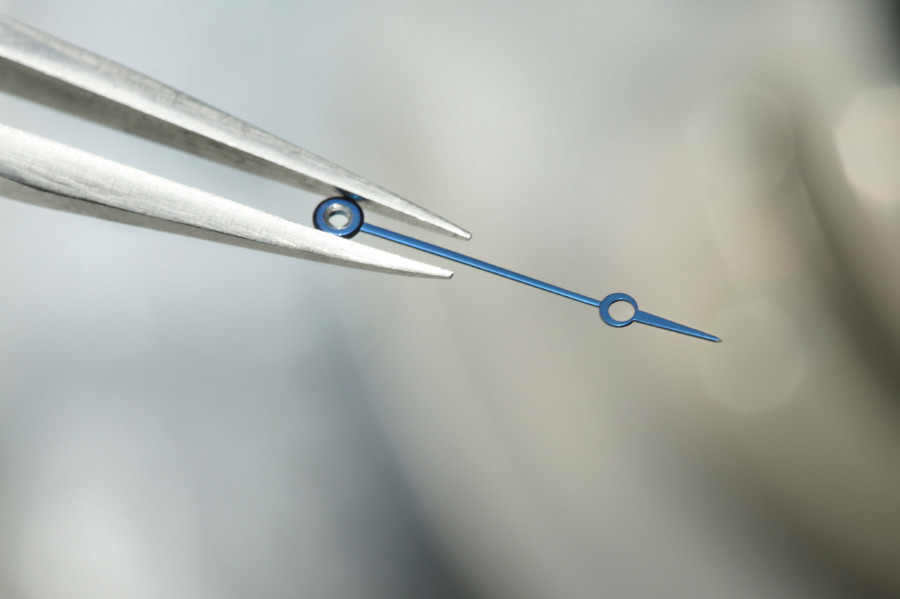

Hands are another distinctive element of watches.

They are generally made of metal, which can be precious, and often made to glow in the dark, thanks to a luminous paste.

As watchmaking has evolved, hands have become a design element that gives personality and uniqueness to the watch. As a result, there are many different types of hands – and we cannot really examine them all. Some of them have become a signature for the Maison.

For example, Breguet hands, used by the famous Parisian watchmaker, are simple sword-shaped hands that feature an open circle towards the ends – before him, they were known as Pomme. Cathedral hands have a metal frame similar to the glass in Gothic churches, and the space inside the frame is filled with luminous paste. This type of hand is widespread in sports and diving watches, as the paste makes them very visible in the dark. Mercedes hands, used by Rolex, are a very famous type of Cathedral hands. Finally, many brands such as Seiko mount Dauphine hands, which were very popular in the 1950s and 1960s, and are instead triangular and faceted in shape.